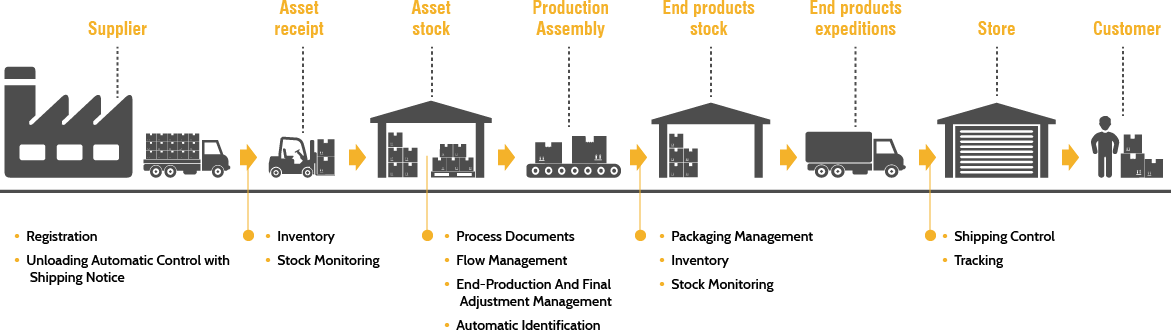

RFID Supply Chain / Warehouse Management

A supply chain is comprised of several tiers which include manufacturers, suppliers, transporters, warehouses, retailers, and the final customers. Warehouses are simply storage areas where organizations store different products received from the suppliers and are part of the supply chain. RFID plays a major role to enhance a more responsive control system for a supply chain ensuring complete end-to-end visibility.

With our IoT, cloud, and RFID-based system, organizations can automate important tasks which take place during receiving and shipping processes. RFID system ensures the identification of products in an instant and provides greater control over items in the warehouse thus increasing the efficiency of identification and validation activities and reducing human errors.

RFID has carried out a study for one of the biggest supply chain companies for item-level tagging and tracking at various levels and DC operations. The project gave us fantastic results and success to our client to decide on RFID Technology and RFID solutions. Studies helped the client achieve all its KPIs. Below are the benefits the system has rendered.

Supply Chain Management is the management of the flow of goods and services, including the movement and storage of raw materials, work-in-progress inventory, and finished goods from point of origin to point of consumption. Since the process can be very extensive, companies are always in search of a way to manage all aspects of it and in return reduce loss and shrinkage among other things.

Currently, companies all over the world are using RFID technology for Supply Chain Management throughout the entire supply chain process enabling them visibility from start to finish. Below are a few benefits of implementing RFID in the supply chain management process.

BENEFITS OF RFID SUPPLY CHAIN AND WAREHOUSE MANAGEMENT SOLUTION

- Reduced shrinkage and pilferage.

- Reduces the total cycle time order until the goods delivery

- Reduced Material Handling

- Allows to check shelves, boxes, and pallets on top without any eye contact

- Increased space utilization for the warehouse

- Increased operational efficiency and productivity in distribution centers and warehouses

- Reduced stockout loss and inventory costs

- Speed and identifications are the promises of RFID in warehouses and supply chains. Inventory accuracy is typically a bit low in warehouses and DCs can improve much with RFID tracking. They can also improve the speed of process activities and understanding of each process step and each shipment.

- Speed of inbound receiving RFID-enabled products, speed of conducting cycle counts, and speed of outbound processing will be much faster and more accurate with RFID solutions and an integrated platform for the supply chain.

INBOUND IMPROVEMENTS:

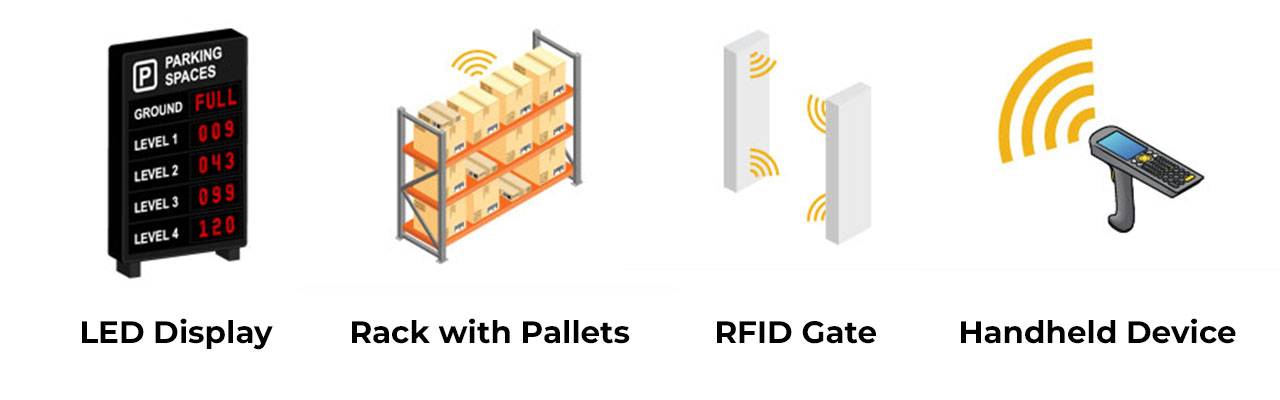

With the integration and familiarity with RFID products, materials can be offloaded onto a truck, pass through a reader (fixed reader, handheld device, RFID Shell, and Belt), and be received into inventory in a matter of seconds.

OUTBOUND IMPROVEMENTS:

Can capture errors at the carton level before assembling pallets and at the pallet level before shipping out the door.

PROCESSING IMPROVEMENTS:

Can locate specific individual products, find lost products, and can stock check cartons faster.

OTHER CONSIDERATIONS INTEGRATION:

RFID can be integrated with SAP, ERP, WMS, etc. Benefits can be realized with an isolated pilot, but ROI does compound as integrations increase.